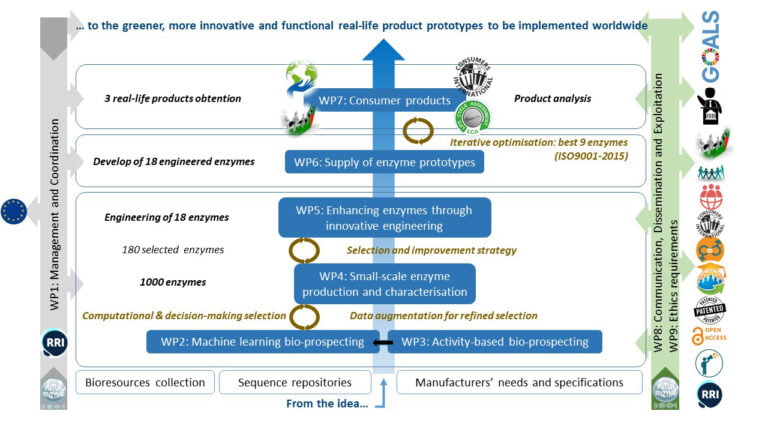

Work plan

The concise rational approach of FuturEnzyme involves nine interacting work packages

WP1: Management and Coordination. Leader: CSIC

Represents the project management and coordination activities.

WP1 includes the following objectives:

- Coordination, management of the project, research, development, IPR and innovation matters.

- Establishing synergies with other consortia coordinators.

Steady contact with Commission representative(s). - Organizing financial and management issues.

- Preparation of the regular cost statements and progress reports.

- Communication with, and organizing the evaluation and feedback of, panels of Experts.

WP2: Machine learning enzyme bioprospecting integrated into an industrial context. Leader: BSC

Implements a smart machine learning platform to screen enzymes demanded by manufacturers.

WP2 proposes the following objectives:

- Compile the manufacturers’ needs for designing 3 real-life and solution-oriented consumer products.

- To pre-select, from public and internal repositories, sequences encoding ondemand enzymes.

- To develop prediction platforms to preselect candidates fulfilling manufacturer’s specifications.

- Establish robust computational and decision-making analyses to select best enzyme candidates.

WP3: Activity-based bio-prospecting for enzymes. Leader: BANGOR

Implements activity-based platforms to screen enzymes demanded by manufacturers.

WP3 proposes the following objectives:

- To screen for novel enzymes which, because of their novelty, could not have been predicted using bioinformatics and computational screens.

- To implement sophisticated activity-based platforms to exploit available and new ad hoc environmentally, geographically and taxonomically diverse bio-resources for entirely novel enzymes demanded by the detergent, textile and cosmetic sectors.

WP4 : Small-scale enzyme production and characterisation. Leader: UHAM

Implements novel systems for producing and characterising selected enzymes and finding the best ones.

The following sub-objectives are addressed in WP4:

- Streamlining semi-automatic, synthetic and cloning technologies, cell-free expression systems, natural host production systems, and beyond state-of-the-art metamorphosis technology for the rapid and efficient expression of target and benchmark enzymes.

- To efficiently generate, through fermentation and downstream processing, enzyme (recombinant, native, biomimetic) materials for activity assessments.

- To characterise the target enzymes with substrates and conditions requested by manufacturers.

- Through a decision-making strategy select enzymes with validated manufacturers’ demands.

- Through a combinatorial strategy to design multi-enzyme blends to process real complex substrates.

WP5: Enhancing enzymes through innovative engineering. Leader: FHNW

Improves the performance of the best enzymes through novel engineering techniques.

The main objective of WP5 is to apply both well established and novel engineering techniques to a sub-set of the best enzymes. The outcome will be to generate enhanced enzyme variants with real potential for manufacturing of laundry, personal care, and textile products. This real potential will be defined on the basis of the inter-relation between high expression level and performance (activity and stability) as high as possible compared to benchmark enzymes. Five complementary techniques will be applied:

- Rational design, through disruptive in silico-directed evolution techniques and algorithms.

- Disruptive engineering computational tools to design highly performance artificial enzymes.

- Synthesis-based site-directed mutagenesis.

- Rational design, through classical structural analysis.

- Immobilization-guided supramolecular engineering in nanoparticles with tailor-made shield.

WP6: Development and supply of best enzyme prototypes. Leader: BIOSYNTH

Establishes a platform for a sustainable supply of the best enzyme formulations.

WP6 aims with high priority to develop and scale up fermentation and downstream processing (DSP) methods, formulation and quality assessments, of the best native and engineered enzymes. After confirming their performance, they will be supplied to downstream application tests, which focuses on the implementation of real-life products integrating these enzymes or products derived from them. The amount of the enzymes to be generated, and thus the fermentation scale, will be fixed depending on the amount needed for the real-life tests needed and through feedback-loops involving enzyme production, formulation development and application tests. Based on enzyme supply costs of best formulations to be integrated in best real-life products to be produced, the safety, risk and environmental impact assessments and the economic feasibility/sustainability of the enzyme supply process will be evaluated in the context of a circular economy.

WP7: Formulation and manufacturing of consumer products. Leader: CLIB

Delivers novel enzymatic strategies for the formulation of innovative real-life consumer products.

The main objective of WP7 is upscaling the appropriately dimensioned trials for

- integrating the best enzymes as ingredients for leading premium liquid detergents and/or unit dose caps products,

- producing textiles with different requirements regarding pretreatment and finishing, and

- for producing enzymatic products of defined size and integrating them into leading cosmetic products. To achieve these objectives, the different enzymes will be tested, hand-in-hand, with small to real validation pilot trials, depending on sample size and product to develop.

WP8: Communication, Dissemination and Exploitation. Leader: ITB

Focuses on dissemination, exploitation and communication.

WP8 will involve the organization of a range of dissemination, communication, training and exploitation activities with the high-level aim of building and maintaining a robust and effective communication culture within the project. The strategy will also foster an informed community of stakeholders and multi-actors interested in and committed to the subject-matter of FuturEnzyme, and to contribute to optimal exploitation of innovative results of the project.

WP9: Ethics requirements. Leader: CSIC

Focuses on ethics requirements.

The objective is to ensure compliance with ‘ethics requirements’.